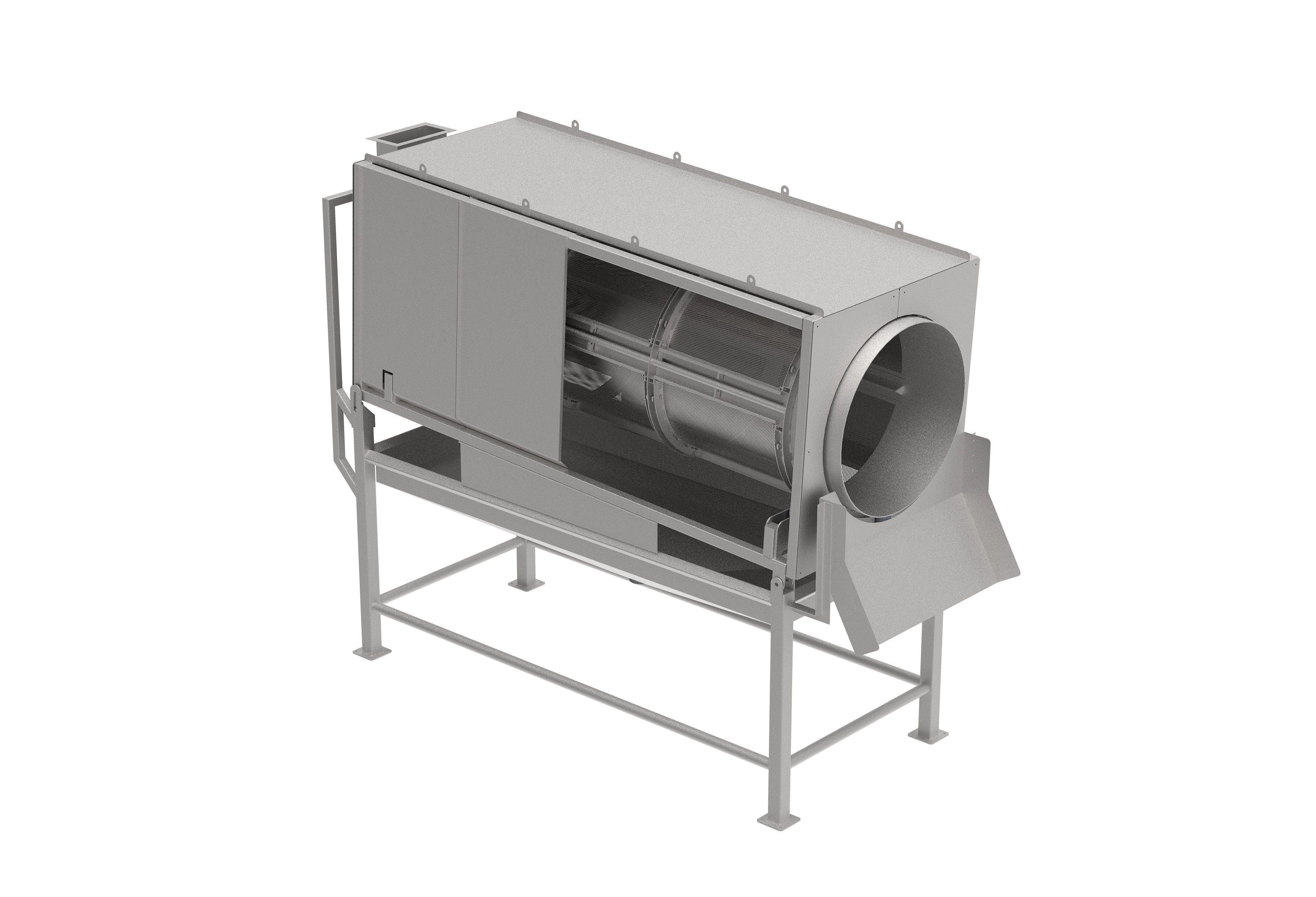

GWI’s Rinsing De-Watering Tumblers are designed for high-capacity, efficient performance in the food processing industry. These industrial rinsing and de-watering tumblers deliver sanitary, precise, and consistent handling of bulk materials, making them ideal for food manufacturing and production lines. Whether you need custom de-watering tumblers for bulk materials or automated solutions for food production, GWI’s systems are built to meet rigorous industry standards while ensuring operational efficiency.

Our California-made rinsing and de-watering tumblers integrate advanced technology to maximize productivity and reduce water usage. With features tailored for durability and performance, these systems are engineered to enhance processing workflows, offering reliable performance even in high-demand environments. GWI’s tumblers provide consistent results, ensuring a clean and efficient process every time.

Key Features:

- High-capacity design for large-scale food processing

- Sanitary construction suitable for food-grade applications

- Precision-engineered for effective rinsing and de-watering

- Automated functionality to streamline production workflows

- Customizable configurations to meet specific processing needs

Competitive Advantages:

- Industry Expertise: Designed by specialists in food-grade rinsing and de-watering technology.

- Customization: Tailored solutions for unique food manufacturing requirements.

- Reliability: Advanced technology ensures consistent, high-performance results.

- Local Manufacturing: Produced in California, offering superior quality and responsive support.

Contact Us

Interested in learning more about how GWI’s Rinsing De-Watering Tumbler Systems can enhance your food processing operations? Contact us today to discuss your needs and discover how our high-efficiency, custom systems can help you achieve your production goals.

Support and Services

- Installation and Training: GWI provides comprehensive installation services and operator training to ensure seamless integration and optimal use of their equipment.

- Maintenance and Support: Ongoing maintenance support and troubleshooting services to keep equipment running efficiently.

- Customization Consultation: Expert consultation to design and customize processing lines tailored to specific requirements.