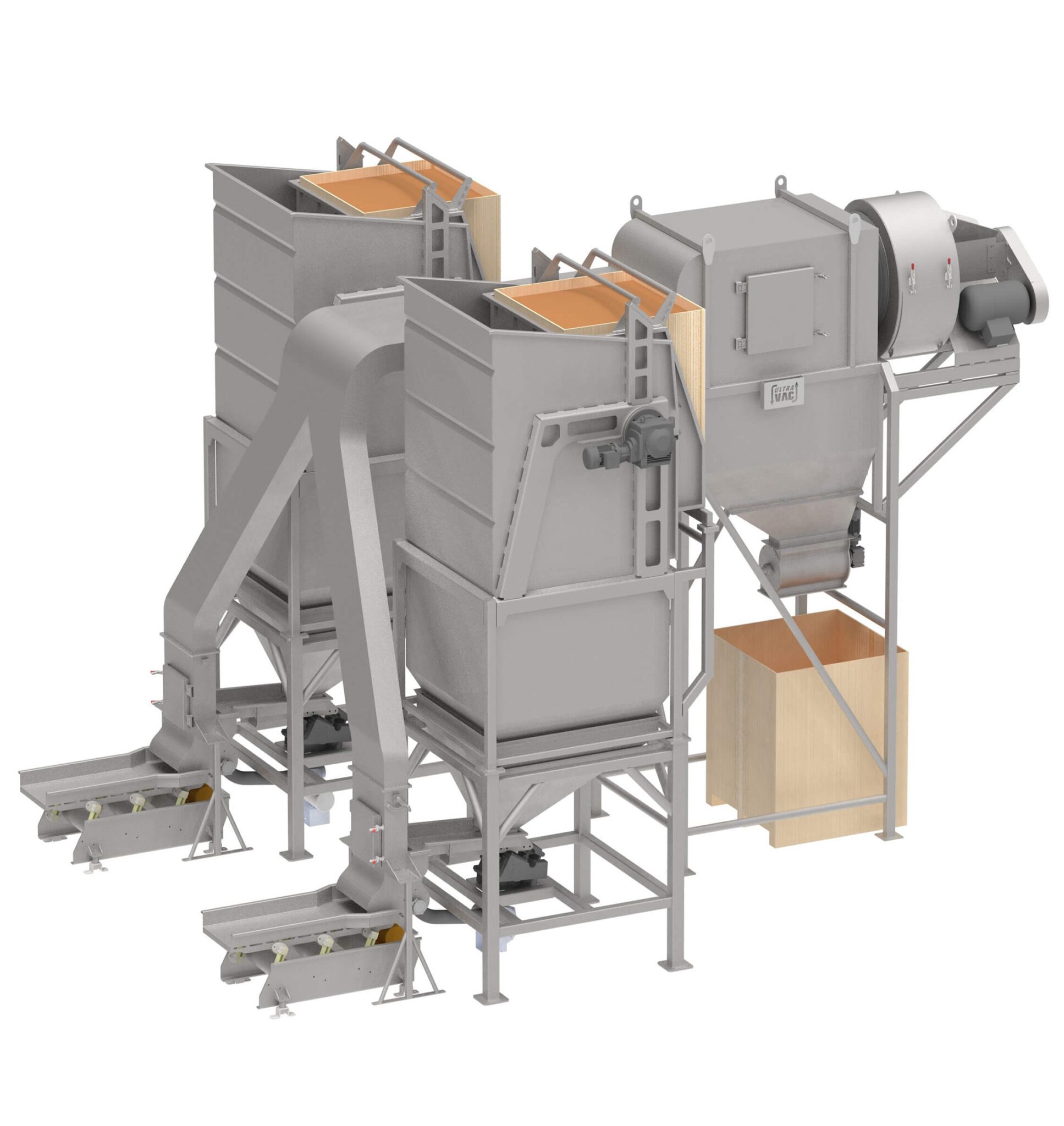

UVS AIR-ASPIRATION SYSTEM

GWI’s UVS air aspiration systems are engineered and designed to provide continuous high-performance separation of unwanted materials from accepted materials with throughputs of up to 60,000 lbs. per hour. The UVS can separate debris from products such as dried fruits, vegetables, leafy products, peppers, cauliflower, broccoli, tomatoes, walnuts, almonds, pistachios, and much more. GWI’s UVS systems are highly efficient user friendly and low maintenance design.

UVS SYSTEMS INCLUDE:

- Separation of almond “doubles” from whole product

- Separation on splits and chips of cashews from whole good product

- Shell separation after cracking (pistachios, walnuts, macadamia, and almonds)

- Stems, sticks, fines and unwanted materials from fruits, nuts, vegetables, and much more

- Wine grape seed separation from undesirable materials

- Pre-cleans a variety of products prior to optical sorting

GWI’s industrial air aspiration systems are essential for grain cleaning processes, effectively separating light impurities from heavier grains. These systems ensure that your grain handling operations are efficient and that the final product is of the highest quality.

Features Include:

- Efficient Separation: Removes chaff, dust, and other light impurities from grains.

- High Capacity: Designed to handle large volumes of grain with consistent performance.

- Durable Construction: Built to withstand the demands of industrial grain processing.

Competitive Advantages of GWI’s UV Sterilization Systems

GWI’s UV sterilization systems offer a range of competitive advantages, including superior disinfection efficiency, customizable designs, energy-efficient operation, and robust durability. These systems help food processors and other industries maintain high hygiene standards, reduce operational costs, and support sustainable practices. Whether you need a turnkey solution or a custom-built system, GWI’s UV sterilization systems provide the performance and reliability needed for safe, efficient operations.

GWI’s UV sterilization systems offer several competitive advantages that set them apart in the food processing and industrial sectors. Here are the key benefits:

1. Superior Sterilization Efficiency

- High-Efficiency UV Disinfection: GWI’s UV sterilization systems are designed to eliminate bacteria, viruses, mold, and other harmful microorganisms with high precision. The powerful UV-C light effectively disinfects surfaces and liquids, making them ideal for ensuring food safety and product purity in food processing environments.

- Non-Chemical Sterilization: UV sterilization by GWI is chemical-free, making it a safe, environmentally friendly method for sanitizing food products, surfaces, and equipment. This eliminates the need for chemical residues and reduces environmental impact.

2. Customizability and Flexibility

- Tailored Solutions: GWI offers fully customizable UV sterilization systems that can be adapted to meet the specific needs of different production environments. Whether you need UV treatment for water, air, or surfaces, GWI designs solutions that fit your requirements, ensuring effective sterilization.

- Versatile Applications: GWI’s UV sterilization systems are versatile and can be used in various industries, including food processing, beverage production, and pharmaceutical manufacturing. This adaptability allows businesses to use UV sterilization in multiple applications, from packaging to conveyor belts.

3. Advanced UV Technology

- State-of-the-Art UV-C Lamps: GWI’s UV systems are equipped with advanced UV-C lamps that provide consistent and effective disinfection. These lamps are engineered for long-lasting performance, ensuring efficient sterilization over extended periods.

- Real-Time Monitoring: GWI’s systems are equipped with real-time monitoring capabilities that ensure optimal UV exposure and efficiency. Operators can track the sterilization process and make adjustments to maintain high disinfection standards.

4. Energy Efficiency and Cost-Effectiveness

- Energy-Efficient Operation: GWI’s UV sterilization systems are designed for low-energy consumption, making them an energy-efficient solution for food processors. This reduces operational costs without compromising the sterilization process, supporting sustainable production practices.

- Low Operational Costs: The non-chemical nature of UV sterilization means fewer consumables are needed, reducing overall costs. Additionally, the long lifespan of UV-C lamps minimizes the need for frequent replacements, further lowering operational expenses.

5. Sanitation and Hygiene

- Chemical-Free Sterilization: UV sterilization provides a non-invasive, chemical-free method of sanitation, ensuring that food products and surfaces are disinfected without leaving harmful residues. This makes GWI’s systems ideal for food processing facilities that prioritize hygiene and safety.

- Easy to Clean: GWI’s UV systems are designed for easy maintenance and cleaning. The equipment’s surfaces are built to minimize crevices and facilitate quick cleaning, ensuring that hygiene standards are met consistently.

6. Durability and Reliability

- Robust Construction: GWI’s UV sterilization systems are built to handle the rigorous demands of continuous operation in industrial environments. Constructed from high-quality materials such as stainless steel, these systems are built to last, offering durability in harsh conditions.

- Reliable Performance: GWI’s UV systems are engineered for long-term reliability, providing consistent sterilization with minimal maintenance. This ensures that production lines remain operational and that hygiene standards are maintained without interruption.

7. Automation and Integration

- Automated UV Sterilization: GWI’s systems can be fully automated, reducing the need for manual intervention and improving efficiency in sterilization processes. Automation allows for consistent sterilization, ensuring that products and surfaces are consistently treated.

- Seamless Integration: GWI’s UV sterilization systems are designed to integrate smoothly into existing production lines, enhancing overall efficiency without significant changes to current operations.

8. Environmental Benefits

- Eco-Friendly Disinfection: GWI’s UV sterilization systems offer an eco-friendly solution for disinfection, eliminating the need for harmful chemicals that may have environmental consequences. UV sterilization is safe for the environment, as it does not produce toxic byproducts or residues.

- Reduced Water and Chemical Usage: By using UV light to sterilize water and surfaces, GWI’s systems help reduce the need for large amounts of water and cleaning chemicals, further supporting environmentally sustainable practices.

9. Turnkey Solutions and Support

- Ready-to-Use Systems: GWI provides turnkey UV sterilization systems that are fully assembled, tested, and ready for immediate use. These systems are designed for quick installation and rapid integration into your existing operations.

- Ongoing Support: GWI offers full technical support and maintenance services to ensure that your UV sterilization systems continue to perform efficiently over time. This includes expert installation, training, and continuous support to meet your operational needs.

Why Choose GWI?

- Expertise and Experience: With extensive experience in designing and manufacturing food processing equipment, GWI provides innovative solutions tailored to your needs.

- Customer-Centric Solutions: Our team works closely with clients to deliver customized raisin processing solutions that enhance operational efficiency and productivity.

- Quality Assurance: Every system is rigorously tested to meet the highest standards of quality and performance before leaving our factory.

Contact Us

Interested in learning more about how GWI’s air aspiration systems can benefit your operation? Contact us today to discuss your needs and find out how our high-efficiency, customizable solutions can help you achieve your production goals.

Support and Services

- Installation and Training: GWI provides comprehensive installation services and operator training to ensure seamless integration and optimal use of their equipment.

- Maintenance and Support: Ongoing maintenance support and troubleshooting services to keep equipment running efficiently.

- Customization Consultation: Expert consultation to design and customize processing lines tailored to specific requirements.