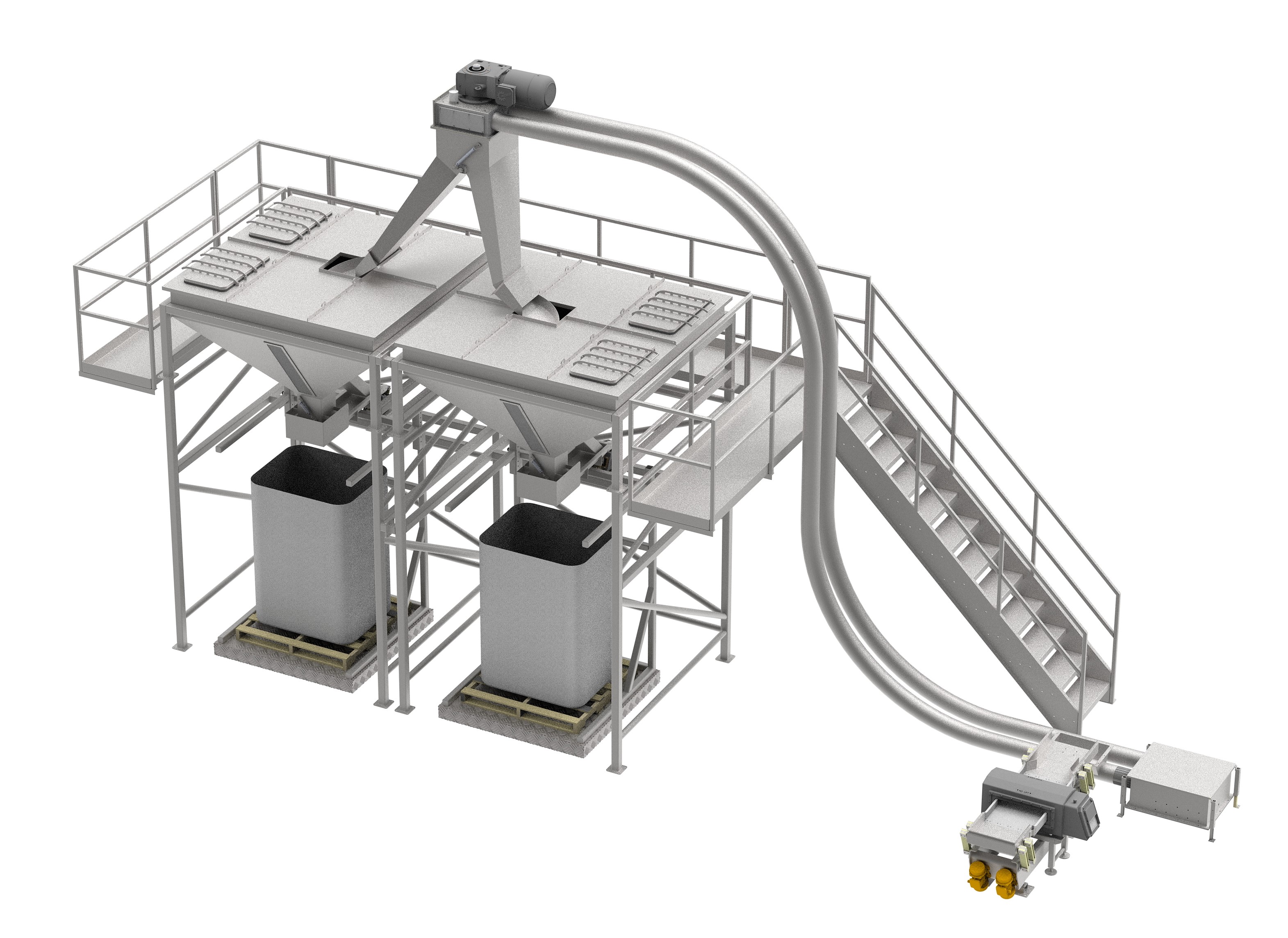

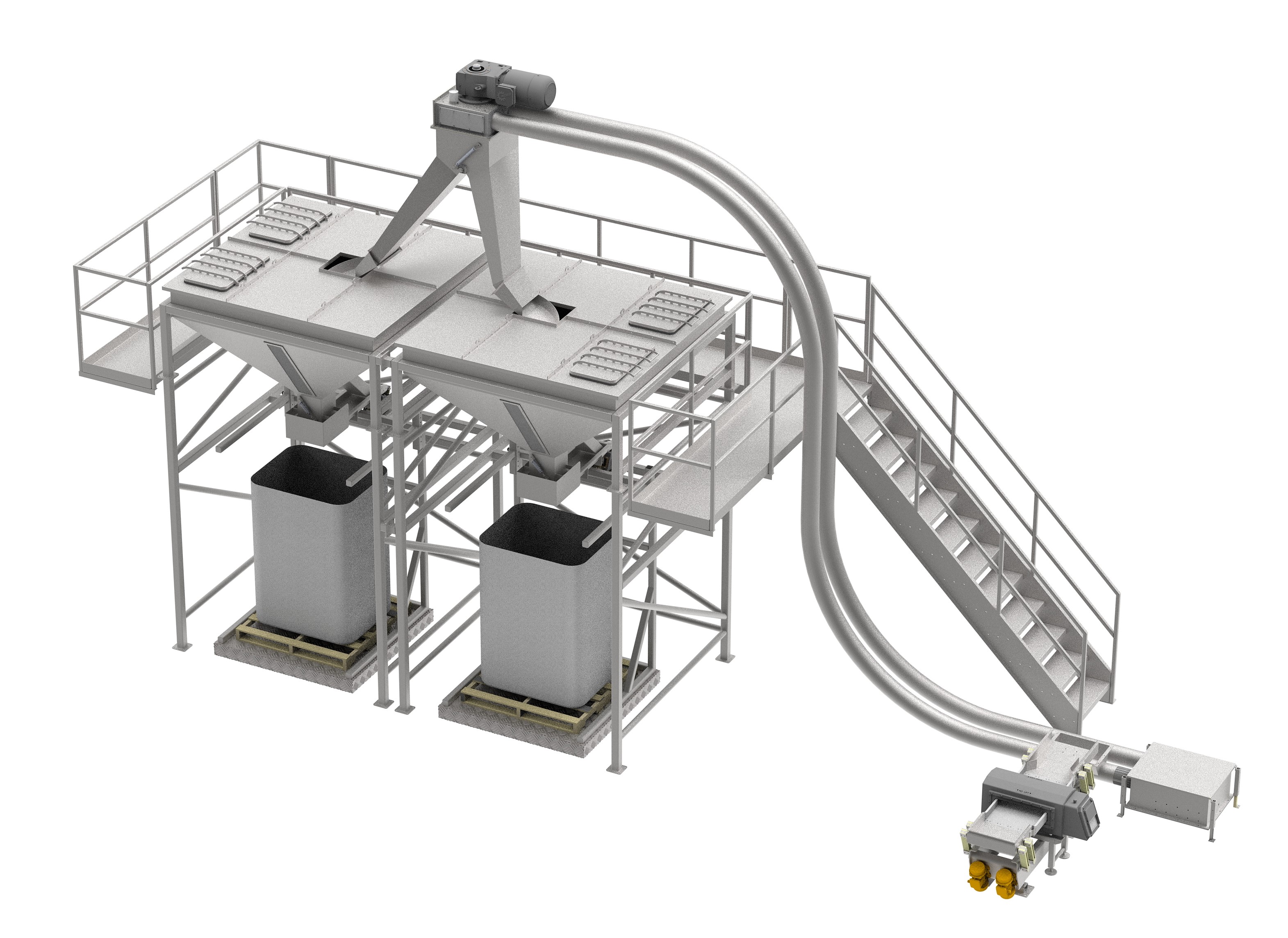

Bulk Filling Weighing Systems

GWI’s Bulk Filling Weighing Systems are designed to enhance efficiency and accuracy in food processing operations, ensuring reliable, high-capacity performance. These industrial bulk filling and

Home » PRODUCT WEIGHING AND FILLING SYSTEMS

GWI offers advanced bulk filling and pack-off equipment designed to improve the efficiency and accuracy of food processing operations. Our high-performance systems are built for bulk handling, packaging, and filling, ensuring that your products are packaged quickly and accurately while maintaining hygiene standards. Whether you need a custom system or a turnkey solution, GWI has the expertise to meet your production needs.

GWI’s bulk filling equipment is designed to handle large quantities of food products efficiently. Our filling systems are built for accuracy, ensuring that each container is filled with the correct amount of product, reducing waste and maximizing productivity.

GWI’s Bulk Filling Weighing Systems are designed to enhance efficiency and accuracy in food processing operations, ensuring reliable, high-capacity performance. These industrial bulk filling and

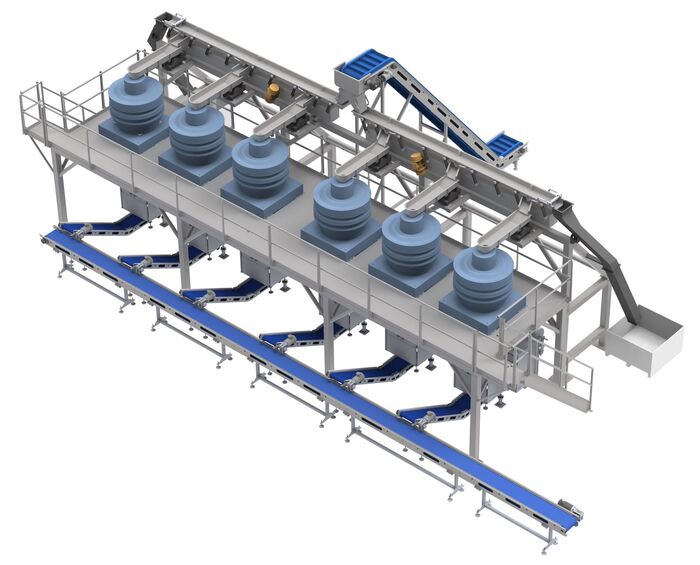

GWI’s Retail Packaging Systems are designed to deliver efficient, high-capacity solutions for food products packaging in the food processing industry. These automated retail packaging systems

GWI’s packaging solutions offer a combination of customization, automation, precision, and durability that makes them a top choice for food processing businesses. With a focus on sanitation, reliability, and efficiency, GWI helps companies optimize their packaging processes, reduce operational costs, and improve product quality. These competitive advantages make GWI’s packaging systems an excellent solution for businesses looking to streamline their operations and stay ahead in the highly competitive food processing industry.

GWI’s packaging solutions offer several competitive advantages that make them stand out in the food processing industry. These advantages include:

Interested in learning more about how GWI’s bulk filling and pack-off equipment can enhance your food processing operations? Contact us today to discuss your specific needs and discover how our high-efficiency, custom solutions can help you achieve your production goals.

Contact our team of experts to find the best nut processing system for your application. We offer comprehensive support from design to installation and maintenance.

Ghazarian Welding Inc. 2903 E. Annadale Ave. Fresno, CA 93725

Tel: (559) 2331210

Fax: (559) 233-6963