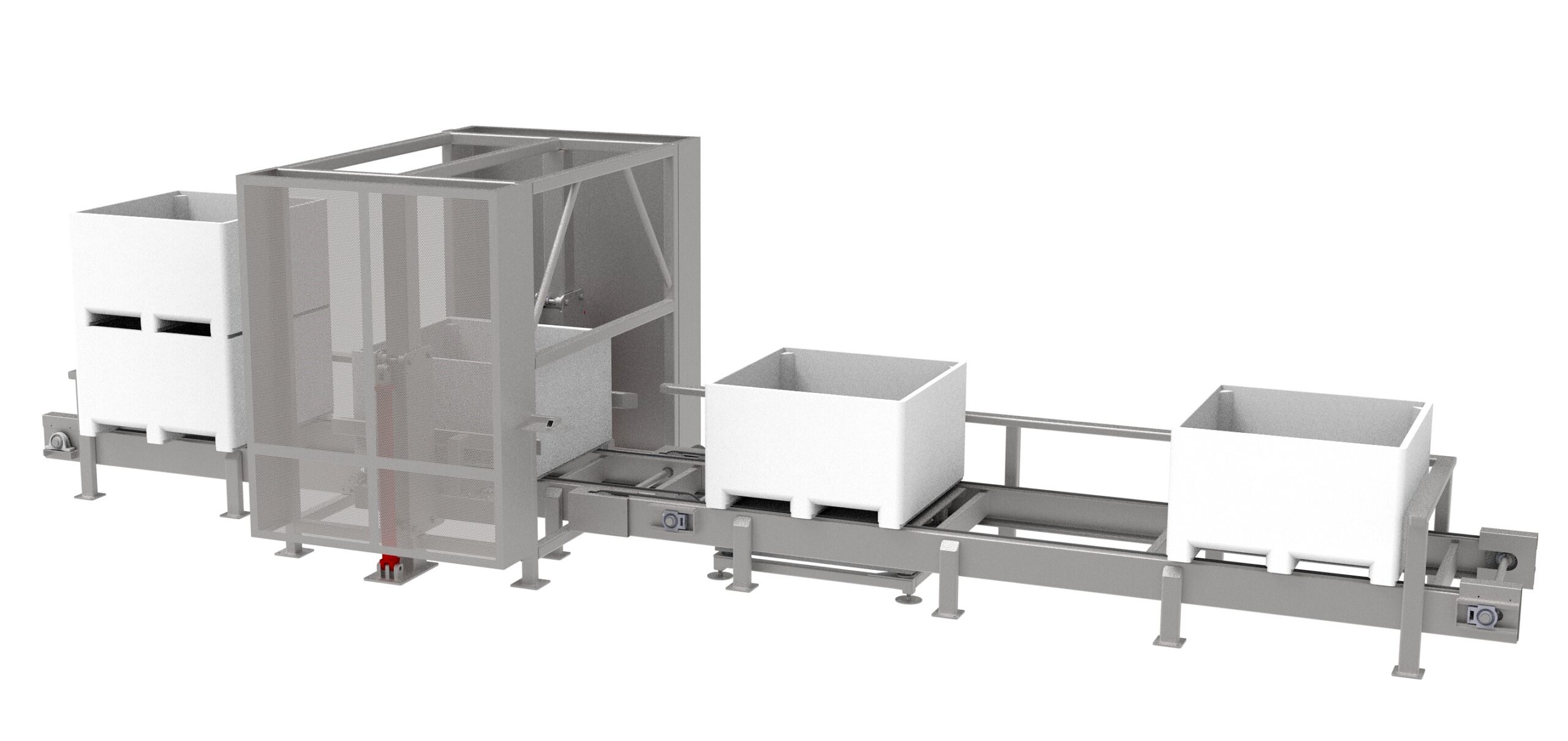

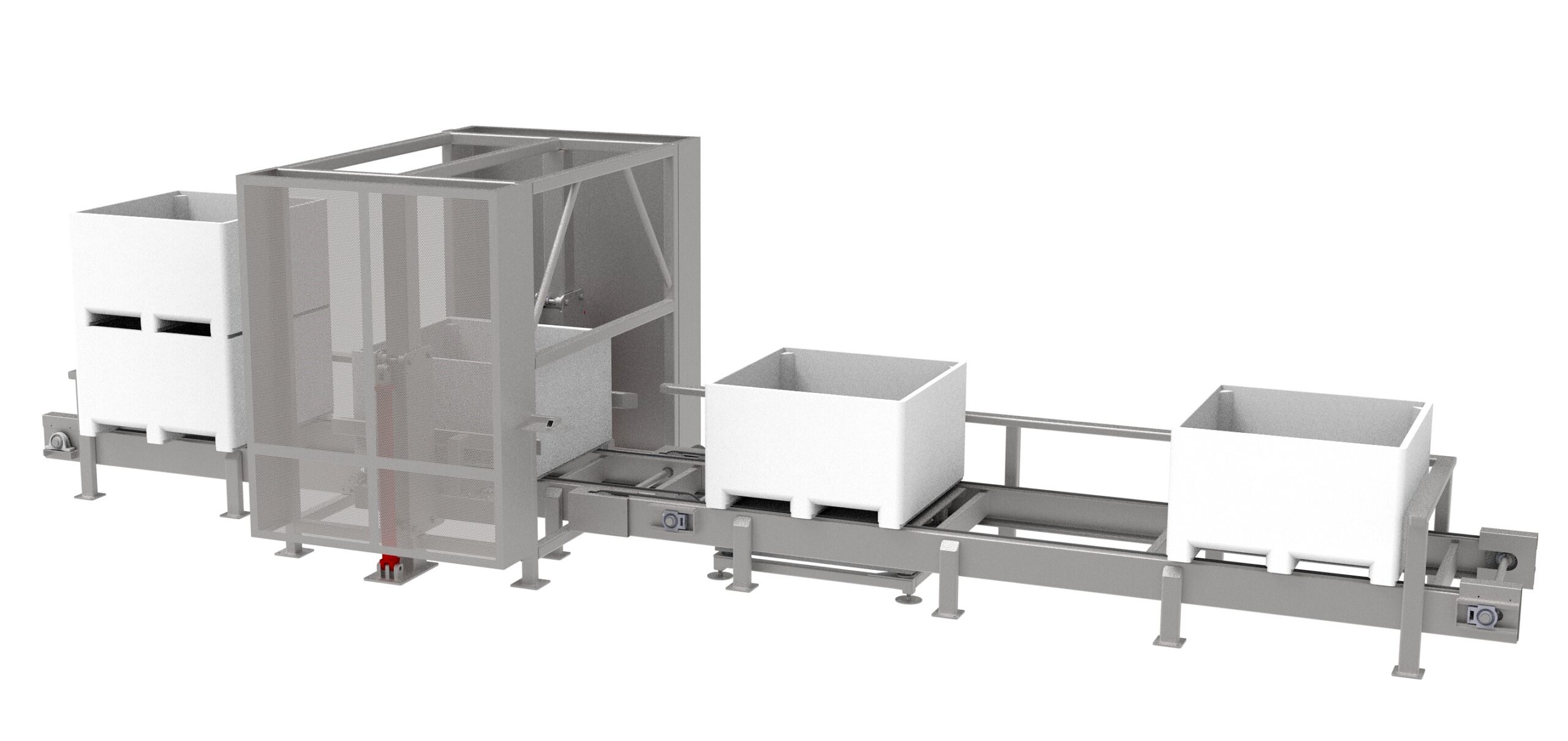

BIN DE-STACK, WEIGH, & RE-STACK SYSTEMS

GWI’s automated bin de-stack, weigh, and re-stack systems are engineered for precise and efficient handling of bulk materials. Our systems are designed to streamline your

Home » DUMPERS

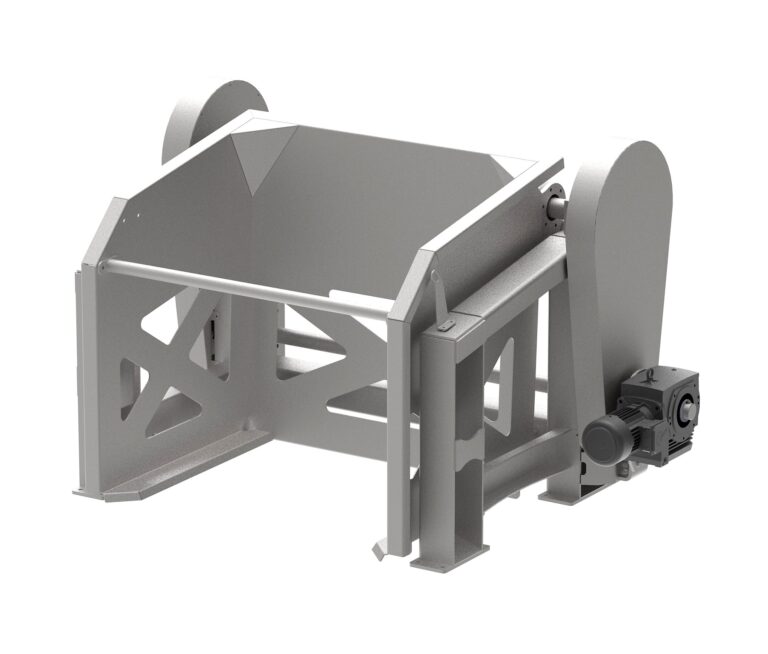

GWI’s dumpers are engineered to provide reliable and efficient bulk material handling solutions for the food processing industry. Designed for precision and durability, our dumpers streamline the loading and unloading process, ensuring your operations run smoothly. From high-efficiency models to fully automated systems, GWI offers custom dumper solutions that meet the specific needs of your facility.

GWI’s industrial dumpers are built to handle the rigorous demands of food production environments. These dumpers ensure that bulk materials such as fruits, vegetables, grains, and other food products are safely and efficiently transferred to the next stage of production without product damage or contamination.

GWI’s automated bin de-stack, weigh, and re-stack systems are engineered for precise and efficient handling of bulk materials. Our systems are designed to streamline your

GWI’s utility-type load dump stack systems are engineered to handle bulk materials precisely and efficiently. Our systems are designed to streamline your operations, ensuring maximum

Our Two-Stage Seal Type Dumpers provide an efficient, high-capacity solution for industrial bin dumping in manufacturing and food processing. With precision engineering, these two-stage sealed

GWI’s Single-Stage Dumpers offer a reliable, high-capacity solution for bulk material handling across industries like food processing and heavy-duty manufacturing. Designed for durability, these single-stage

GWI’s Two-Stage Drum Barrel Dumpers offer a high-capacity, precision-engineered solution for industries requiring reliable and efficient bulk material handling. Designed with advanced technology, these two-stage

GWI’s Overhead Center Pivot Dumpers offer an advanced solution for high-capacity bulk material handling across industries, particularly in food processing and manufacturing. Designed with durability

GWI’s Floor-Level Load Dumpers offer a high-capacity solution for efficient, secure material handling at floor level, ideal for industrial and food processing environments. Designed for

GWI’s dumpers stand out due to their high level of customization, durability, efficiency, and focus on sanitation. With fully automated options, food-grade materials, and turnkey solutions, GWI delivers dumpers that meet the rigorous demands of food processing and industrial material handling environments. Their commitment to safety, efficiency, and long-term reliability makes GWI dumpers a competitive choice for businesses seeking to optimize their bulk material handling operations.

GWI’s dumpers offer several competitive advantages that make them a top choice for food processing and industrial material handling:

Interested in learning more about how GWI’s dumpers can benefit your food processing or industrial operations? Contact us today to discuss your needs and discover how our high-efficiency, custom solutions can help you achieve your production goals.

Contact our team of experts to find the best nut processing system for your application. We offer comprehensive support from design to installation and maintenance.

Ghazarian Welding Inc. 2903 E. Annadale Ave. Fresno, CA 93725

Tel: (559) 2331210

Fax: (559) 233-6963