Industrial De-Clumping Solutions for Dried Commodities

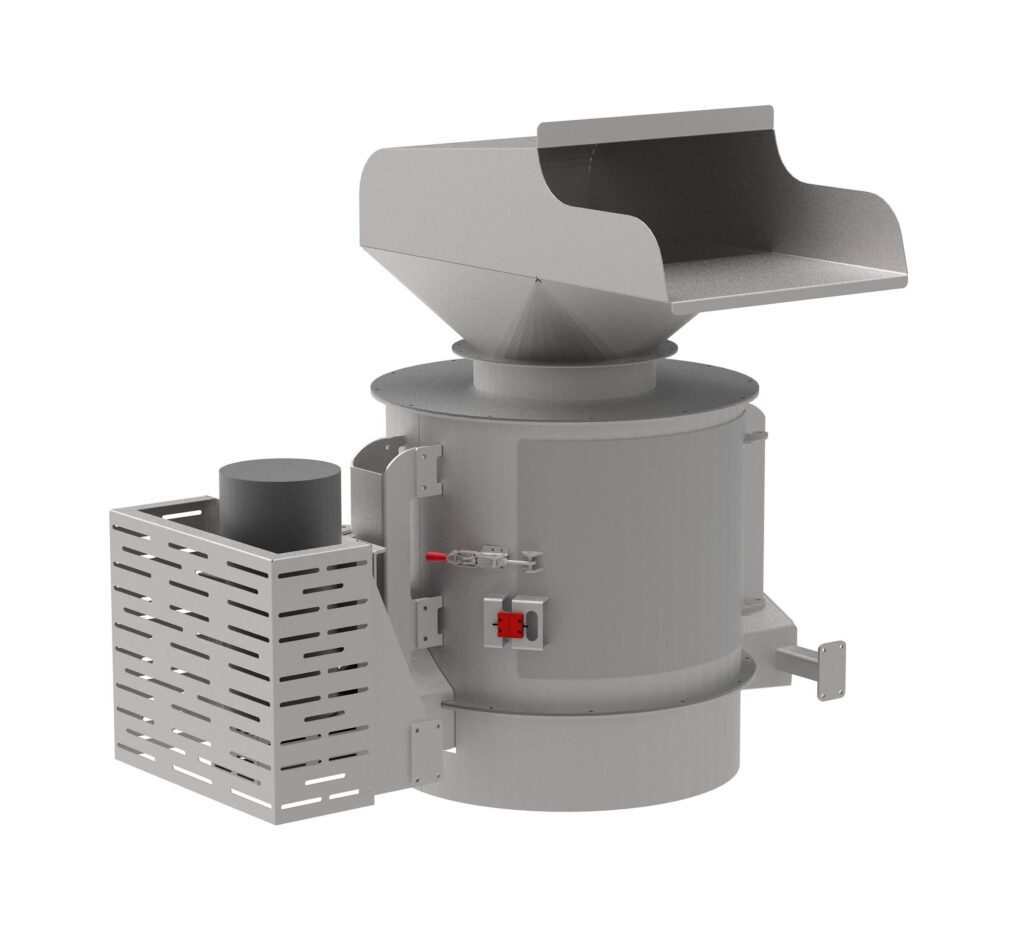

GWI’s de-clumpers are engineered to ensure smooth, efficient processing by eliminating clumps in bulk materials. Whether you’re handling powdered food products or other bulk materials, our de-clumpers offer the high efficiency and reliability you need to maintain product quality and streamline your production processes.

In the food processing industry, maintaining consistent material flow is critical. GWI’s industrial de-clumpers are designed to break up clumps in bulk materials, ensuring smooth, uninterrupted processing. These machines are essential for operations that handle powders, grains, and other materials prone to clumping.

Key Features:

- Robust Design: Built to withstand the demands of industrial food processing environments.

- Consistent Performance: Effectively reduces clumps, ensuring uniform material flow.

- Versatile Applications: Suitable for a wide range of food products, including powders, granules, and more.

Competitive Advantages

GWI’s de-clumpers are competitive in the market, offering robust design, high efficiency, and customization options that cater specifically to the food processing industry. When comparing GWI’s de-clumpers to those of competitors several key aspects stand out:

1. Design and Build Quality

- GWI’s de-clumpers are known for their robust design, specifically engineered for high-throughput operations in the food processing industry. They are designed to handle bulk materials efficiently, ensuring continuous flow and preventing blockages.

2. Efficiency and Performance

- GWI’s de-clumpers are optimized for efficiency, with a focus on maintaining high throughput while minimizing downtime. This makes them ideal for large-scale food processing operations where maintaining a steady flow is critica.

3. Customization and Integration

- GWI offers a high level of customization, allowing their de-clumpers to be tailored to specific processing needs. This flexibility makes them suitable for various food processing applications, from powdered food products to bulk material handling.

4. Sanitation and Maintenance

- GWI’s de-clumpers are designed with sanitation in mind, using food-grade materials and easy-to-clean designs to maintain hygiene in food processing environments.

Why Choose GWI?

- Expertise and Experience: With extensive experience in designing and manufacturing food processing equipment, GWI provides innovative solutions tailored to your needs.

- Customer-Centric Solutions: Our team works closely with clients to deliver customized raisin processing solutions that enhance operational efficiency and productivity.

- Quality Assurance: Every system is rigorously tested to meet the highest standards of quality and performance before leaving our factory.

Contact Us

Interested in learning more about how GWI’s de-clumpers can benefit your food processing operations? Contact us today to discuss your needs and discover how our efficient, customizable solutions can help you achieve your production goals.

Support and Services

- Installation and Training: GWI provides comprehensive installation services and operator training to ensure seamless integration and optimal use of their equipment.

- Maintenance and Support: Ongoing maintenance support and troubleshooting services to keep equipment running efficiently.

- Customization Consultation: Expert consultation to design and customize processing lines tailored to specific requirements.