Industrial Product Singulating Systems

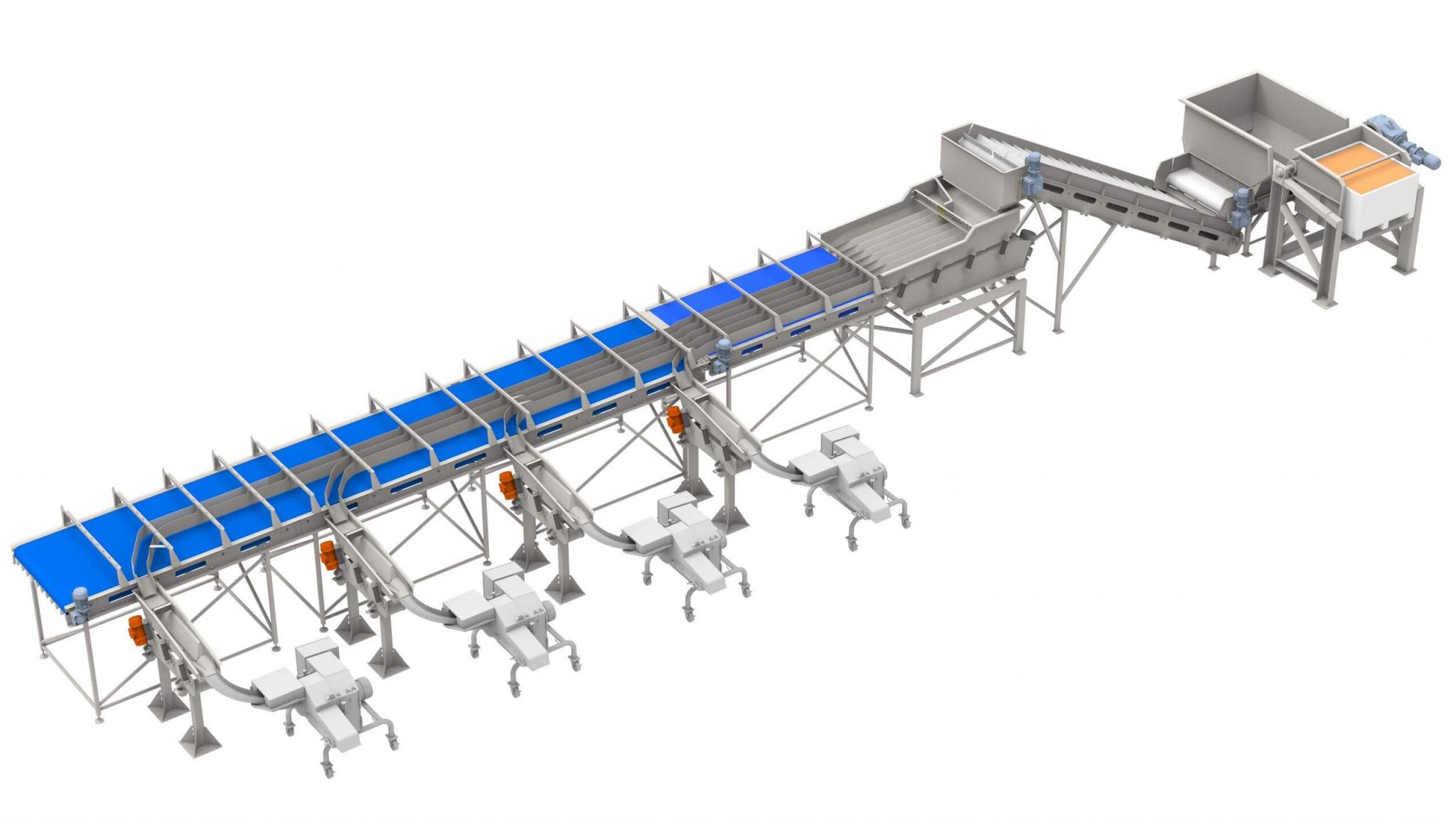

GWI’s Product Singulating Systems are a very efficient way to singulate products for further processing such as slicing, crushing, and or retail packing. Our singulating systems can process in a range from 2 to 15 tons per hour and can be configured to work within your existing facility footprint, or can be designed for new building applications to ensure high efficient productivity.

Our industrial product singulating systems are engineered to provide high-efficiency solutions for food manufacturers. Designed to streamline the sorting and handling of individual products, our systems are essential for maintaining efficiency and precision in large-scale production environments. These systems are designed to meet the demands of modern food processing operations.

GWI’s product singulating systems stand out due to their strong focus on customization, hygiene, and advanced automation. These features make them an excellent choice for food processors looking for reliable, efficient, and adaptable solutions to enhance their production lines. Whether you’re handling bulk products, delicate items, or need to optimize for food safety, GWI’s systems offer the flexibility and performance needed to meet a wide range of processing challenges.

PROCESSING COMPONENTS

Bin Dumping

Metering conveyance

Lane orientating

Singulation

Distribution

Key Features and Capabilities

Automated Product Singulation

- Efficiency: GWI’s systems automate the singulation process, reducing the need for manual sorting and handling. This automation ensures that products are consistently and accurately separated, which is crucial for maintaining high production speeds and minimizing errors.

- Precision: The systems are engineered to handle products with care, ensuring that each item is accurately aligned and oriented for downstream processes.

High-Capacity Handling

- Large-Scale Operations: GWI’s singulating systems are capable of handling large volumes of products, making them ideal for high-capacity production environments. This capability ensures that production lines can operate at peak efficiency without bottlenecks or delays.

- Versatile Designs: The systems are versatile and can be configured to handle a wide range of products, from small, delicate items to larger, more robust products.

Customizable Solutions

- Tailored to Your Needs: GWI offers customizable singulating systems that can be tailored to the specific needs of your operation. Whether you need systems designed for specific product types or for integration with existing equipment, GWI can provide a solution that fits your requirements.

- Scalable Options: The modular design of GWI’s systems allows for easy scalability, enabling businesses to expand their operations as needed without significant reconfiguration.

Sanitary Design for Food Safety

- Hygienic Construction: The systems are built with food safety in mind, featuring smooth surfaces and easy-to-clean components. This design minimizes the risk of contamination, ensuring compliance with food safety regulations.

- Durable Materials: Constructed from high-quality materials, GWI’s singulating systems are designed to withstand the rigors of continuous use in food processing environments, providing long-lasting reliability.

Advanced Technology Integration

- Real-Time Monitoring: GWI integrates advanced control systems that allow for real-time monitoring and adjustments, ensuring that the singulation process remains efficient and accurate.

- Data Analytics: The systems are equipped with data analytics capabilities, enabling operators to track key performance metrics, optimize operations, and improve overall efficiency.

Energy Efficiency

- Cost-Effective Operation: GWI’s systems are designed to minimize energy consumption, reducing operational costs while maintaining high levels of performance.

- Sustainable Solutions: The focus on energy efficiency supports sustainability goals, making GWI’s singulating systems an environmentally friendly choice for food processors.

Why Choose GWI?

Expertise and Experience

With extensive experience in designing and manufacturing food processing equipment, GWI provides innovative solutions tailored to your needs.

Customer-Centric Solutions

Our team works closely with clients to deliver customized raisin processing solutions that enhance operational efficiency and productivity.

Quality Assurance

Every system is rigorously tested to meet the highest standards of quality and performance before leaving our factory.

Contact Us

Ready to optimize your product singulation operations? Contact GWI today to learn more about our customized solutions. Our experts are here to help you find the perfect system for your needs.

Support and Services

Installation and Training

GWI provides comprehensive installation services and operator training to ensure seamless integration and optimal use of their equipment.

Maintenance and Support

Ongoing maintenance support and troubleshooting services to keep equipment running efficiently.

Customization Consultation

Expert consultation to design and customize processing lines tailored to specific requirements.