Industrial Bin Handling Systems

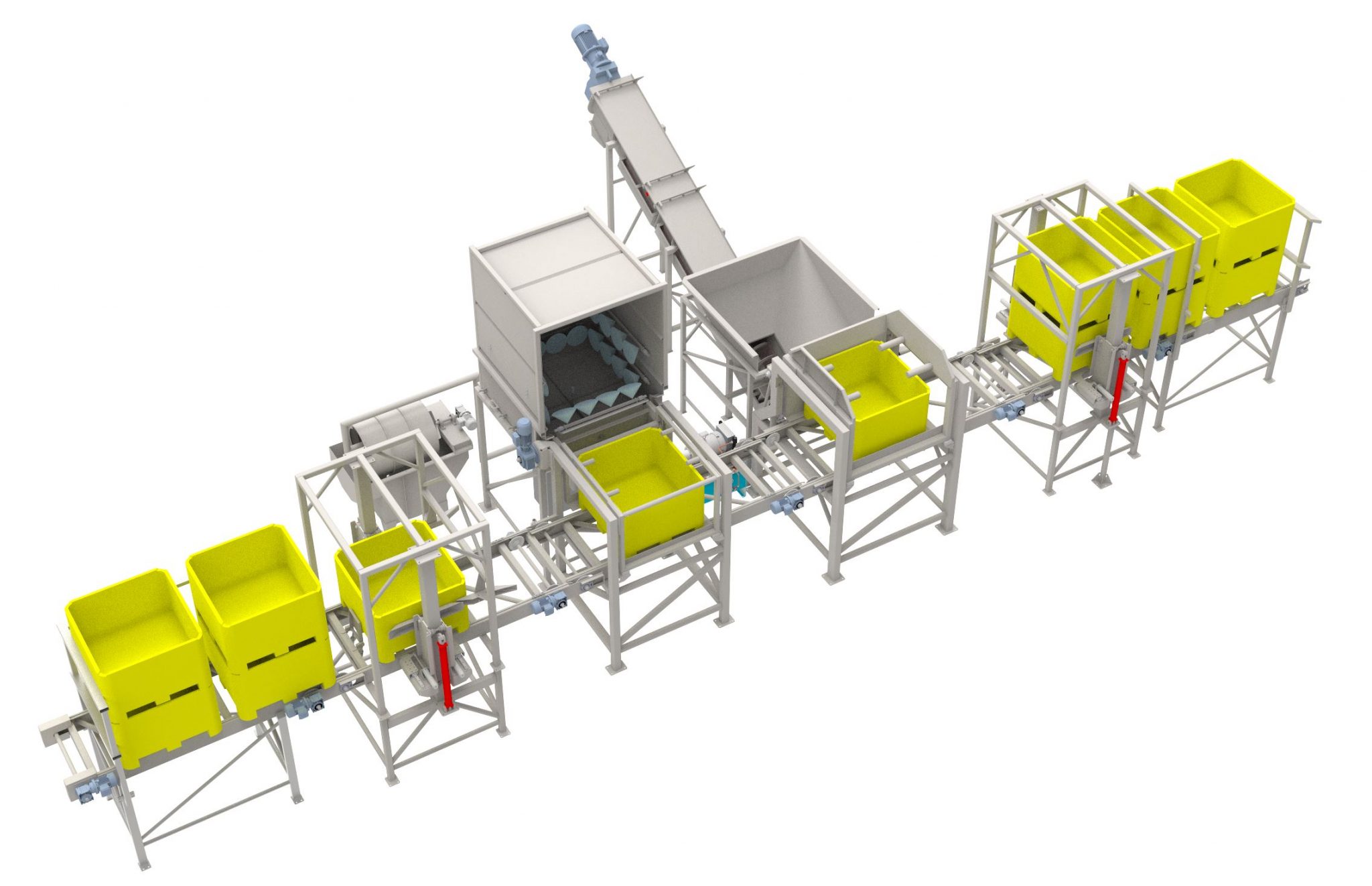

GWI’s industrial bin handling systems are engineered to provide high-efficiency solutions for food manufacturers. Designed to streamline the movement, storage, and processing of bulk materials, our systems are essential for maintaining efficiency and safety in large-scale production environments.

GWI’s bin handling systems stand out due to their strong focus on customization, sanitation, advanced automation, and scalability. These features make them a reliable and efficient choice for food processing operations that require high standards of hygiene, flexibility in handling different types of bins and materials, and the ability to scale operations as needed.

Whether used for ingredient handling, product transfer, waste management, or logistics, these systems are designed to meet the diverse needs of modern food manufacturing facilities. The versatility of GWI’s bin handling systems make them suitable for a wide range of applications, helping to improve productivity and maintain high standards of quality and safety in food production.

PROCESS INCLUDE:

- De-stacking units

- Single or double bin dumping

- Product transfer metering conveyance

- Bin washing / rinsing

- Bin re-stacking units

Fields marked with an * are required

Key Features and Capabilities

Automated Bin Handling

- Efficiency: GWI’s systems are automated to reduce the need for manual labor, ensuring quick and consistent movement of bins throughout the production process.

- Precision: Automation improves the accuracy of bin placement and handling, minimizing the risk of errors that can lead to downtime or product loss.

High Capacity Handling

- Large-Scale Operations: The systems are designed to handle large volumes of bins, making them suitable for high-capacity production environments.

- Versatile Designs: These systems can accommodate a wide range of bin sizes and types, providing flexibility for various production needs.

Customizable Solutions

- Tailored to Your Needs: GWI offers fully customizable bin handling systems that can be adapted to specific production requirements. Whether for small-scale or mass production, the systems can be configured to meet unique operational demands.

- Scalable Options: The modular design allows for easy scalability, enabling businesses to expand their operations without significant disruptions.

Sanitary and Hygienic Design

- Food Safety Compliance: The systems are built with smooth surfaces and easy-to-clean components, ensuring they meet stringent food safety standards.

- Durable Materials: Constructed from high-quality materials that are resistant to wear and tear, these systems are designed for longevity and reliability in demanding environments.

Advanced Technology Integration

- Real-Time Monitoring: GWI’s systems incorporate advanced control systems that allow for real-time monitoring and adjustments, ensuring optimal performance at all times.

- Data Analytics: The systems are equipped with data analytics capabilities to track key performance metrics, helping businesses optimize their operations.

Energy Efficiency

- Cost-Effective Operation: GWI’s bin handling systems are designed to minimize energy consumption, reducing operational costs while maintaining high efficiency.

- Sustainable Solutions: The focus on energy efficiency also supports sustainability goals by lowering the overall environmental impact of production operations.

Durability

- Built to withstand the rigors of continuous industrial use.

Applications:

1. Ingredient Handling

- Application: Efficient movement of raw materials and ingredients from storage bins to various processing stations.

- Benefits: Ensures that materials are delivered to the production line quickly and efficiently, reducing the risk of delays and maintaining a steady production flow.

2. Product Transfer

- Application: Transferring semi-finished or finished products between different stages of the production line.

- Benefits: Streamlines the production process by automating the movement of products, reducing the need for manual handling and minimizing the risk of damage or contamination.

3. Bulk Material Storage

- Application: Storing bulk materials such as grains, flours, powders, or other food ingredients in bins and efficiently retrieving them when needed.

- Benefits: Maximizes storage efficiency and ensures that materials are readily available for production, reducing the risk of stockouts and production delays.

4. Batch Processing

- Application: Handling and transferring specific quantities of materials required for batch processing.

- Benefits: Supports precise measurement and mixing of ingredients, ensuring consistency and quality in each batch produced.

5. Waste Management

- Application: Handling and transporting waste materials, by-products, or unusable products to designated disposal or recycling areas.

- Benefits: Keeps the production environment clean and safe, and ensures that waste is managed efficiently and in compliance with environmental regulations.

6. Packaging Line Support

- Application: Moving finished products from production to packaging stations using bins, ensuring a smooth and continuous flow to the packaging line.

- Benefits: Enhances the efficiency of packaging operations by ensuring that products are delivered to the packaging line in a timely manner.

7. Sanitary Transfer

- Application: Transferring sensitive or perishable products in a sanitary manner to maintain product quality and safety.

- Benefits: Ensures that products remain uncontaminated and meet food safety standards, which is particularly important for high-risk or perishable items.

8. Custom Product Handling

- Application: Managing the handling of specialized products that require specific handling techniques, such as fragile or delicate items.

- Benefits: Reduces product damage and waste, ensuring that even delicate items are handled safely and efficiently.

9. Logistics and Distribution

- Application: Handling and moving products in bins for storage, transport, or distribution to other locations or facilities.

- Benefits: Streamlines the logistics process by providing an efficient means of moving products in bulk, reducing handling time, and lowering labor costs.

Why Choose GWI?

- Expertise and Experience: With extensive experience in designing and manufacturing food processing equipment, GWI provides innovative solutions tailored to your needs.

- Customer-Centric Solutions: Our team works closely with clients to deliver customized raisin processing solutions that enhance operational efficiency and productivity.

- Quality Assurance: Every system is rigorously tested to meet the highest standards of quality and performance before leaving our factory.

Contact Us

Ready to optimize your bin handling operations? Contact GWI today to learn more about our customized solutions. Our experts are here to help you find the perfect system for your needs.

Support and Services

- Installation and Training: GWI provides comprehensive installation services and operator training to ensure seamless integration and optimal use of their equipment.

- Maintenance and Support: Ongoing maintenance support and troubleshooting services to keep equipment running efficiently.

- Customization Consultation: Expert consultation to design and customize processing lines tailored to specific requirements.