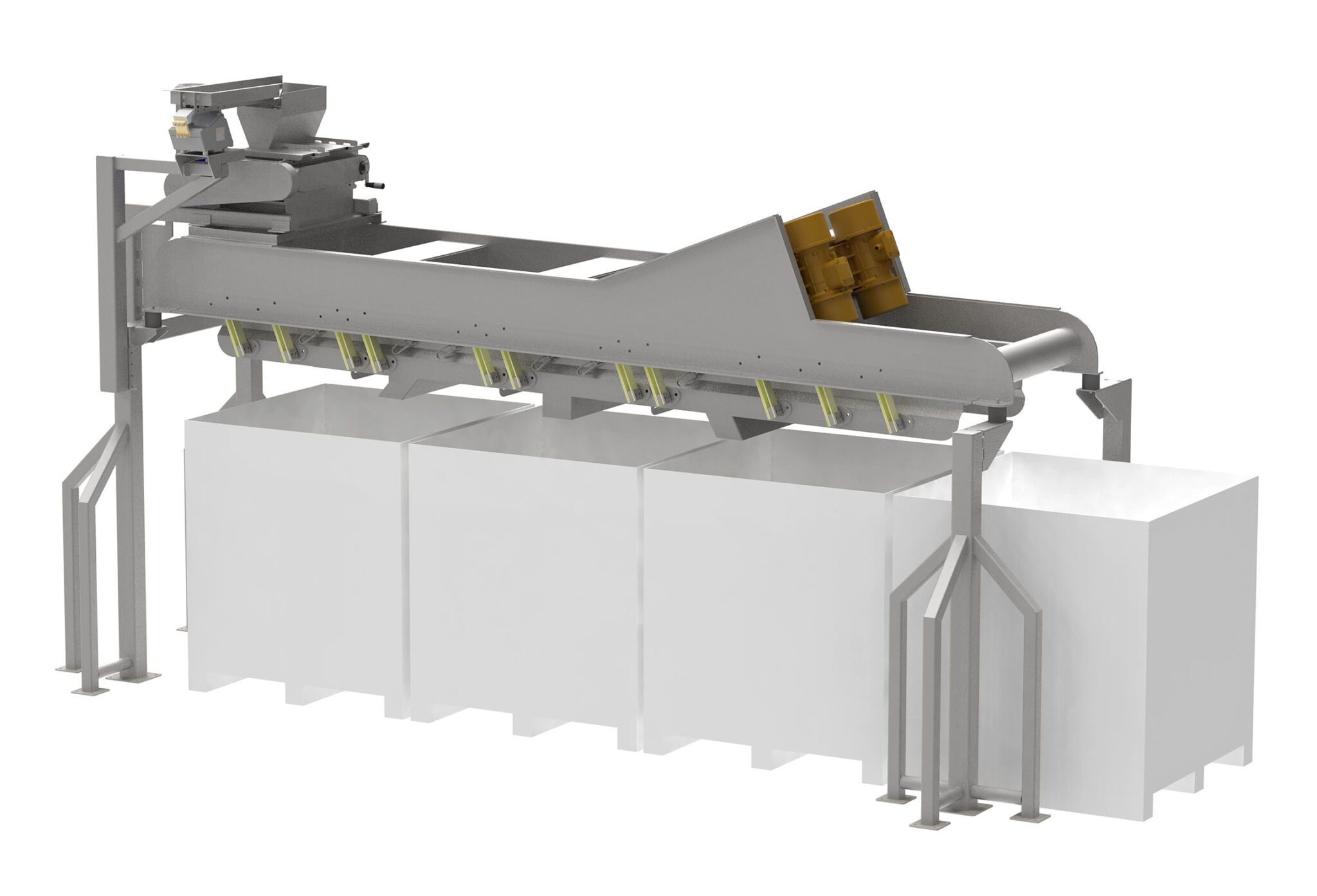

GWI’s Nut Dicer & Sizer Combo Machine is engineered for high-capacity, efficient nut dicing and sizing tailored to the needs of the food processing industry. Designed for precision and durability, this industrial nut dicing and sizing equipment delivers consistent, accurate cuts, optimizing your production line for seamless operation. Whether you need a custom nut dicer and sizer for bulk processing or an automated nut dicing solution with advanced technology, GWI’s combo machine offers flexibility and reliability.

Our California-made nut dicer and sizer integrates cutting-edge technology to enhance productivity and ensure product uniformity. Built with a focus on high-volume applications, the system supports heavy-duty nut dicing and sizing with minimal maintenance, making it an ideal choice for manufacturers looking to boost efficiency and reduce downtime.

Key Features:

- High-capacity dicing and sizing for bulk nut processing

- Precision-engineered for accurate, uniform cuts

- Automated operation to streamline food processing workflows

- Durable, heavy-duty design for industrial use

- Customizable to meet specific production needs

Competitive Advantages:

- Industry Expertise: Developed by specialists in food-grade dicing and sizing equipment.

- Customization: Tailored configurations for unique processing requirements.

- Reliability: Advanced technology ensures consistent, high-capacity performance.

- Local Manufacturing: Produced in California, ensuring top quality and accessible support.

Contact Us

Interested in learning more about how GWI’s Nut Dicer & Sizer Combo Machine Systems can enhance your food processing operations? Contact us today to discuss your needs and discover how our high-efficiency, custom systems can help you achieve your production goals.

Support and Services

- Installation and Training: GWI provides comprehensive installation services and operator training to ensure seamless integration and optimal use of their equipment.

- Maintenance and Support: Ongoing maintenance support and troubleshooting services to keep equipment running efficiently.

- Customization Consultation: Expert consultation to design and customize processing lines tailored to specific requirements.