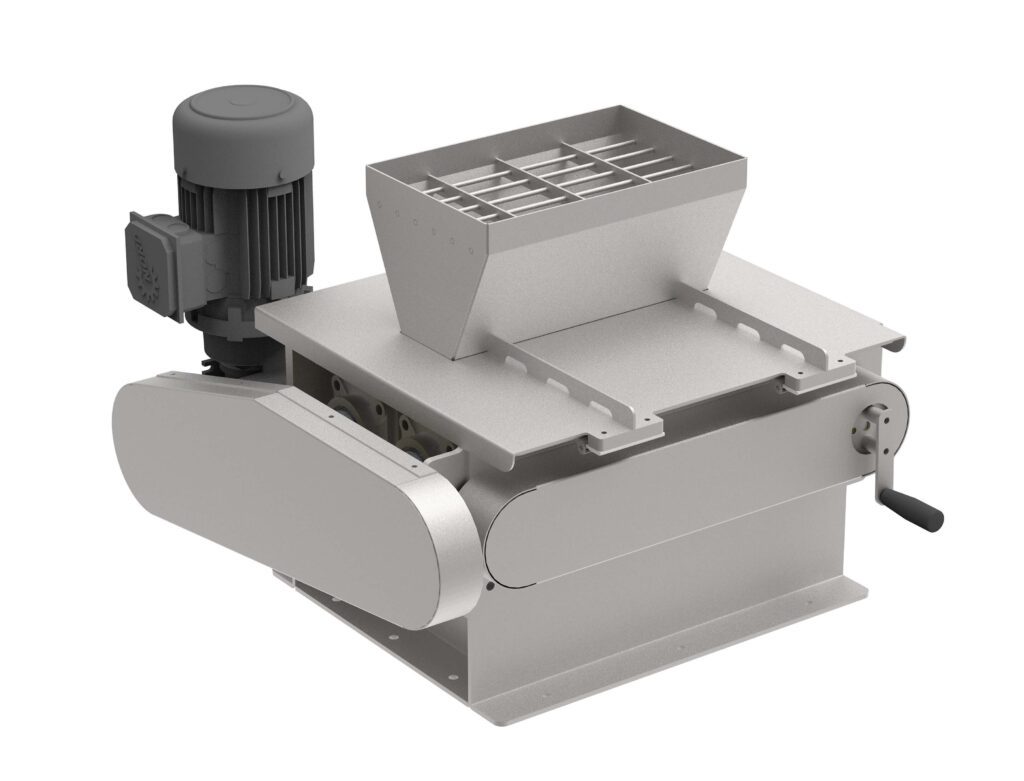

GWI’s Nut Breakers & Dicers are precision-engineered for high-capacity nut breaking and dicing to meet the demands of the food processing industry. Designed for both durability and efficiency, these industrial nut breaking and dicing machines ensure consistent results, optimizing productivity in bulk applications. For businesses looking for custom nut breaking and dicing solutions or automated machines to streamline production, GWI offers advanced, reliable systems that maintain product integrity.

Our California-made nut breakers and dicers feature cutting-edge technology, making them ideal for large-scale operations requiring precise, sanitary processing. Built with heavy-duty materials, these systems provide reliable performance, even in high-demand environments. GWI’s equipment is customizable, allowing you to select features suited for your specific processing needs, whether in food manufacturing or industrial applications.

Key Features:

- High-capacity design for efficient nut breaking and dicing

- Precision-engineered to ensure uniform product size

- Automated functions to increase productivity and reduce manual labor

- Heavy-duty construction for durability in industrial environments

- Customizable options tailored to specific industry requirements

Competitive Advantages:

- Industry Expertise: Developed by specialists in nut processing and food-grade equipment.

- Customization: Tailored configurations meet diverse processing needs.

- Reliability: Advanced technology ensures consistent, high-volume performance.

- Local Manufacturing: Produced in California, providing quality assurance and accessible support.

Contact Us

Interested in learning more about how GWI’s Nut Breakers & Dicer Systems can enhance your food processing operations? Contact us today to discuss your needs and discover how our high-efficiency, custom systems can help you achieve your production goals.

Support and Services

- Installation and Training: GWI provides comprehensive installation services and operator training to ensure seamless integration and optimal use of their equipment.

- Maintenance and Support: Ongoing maintenance support and troubleshooting services to keep equipment running efficiently.

- Customization Consultation: Expert consultation to design and customize processing lines tailored to specific requirements.