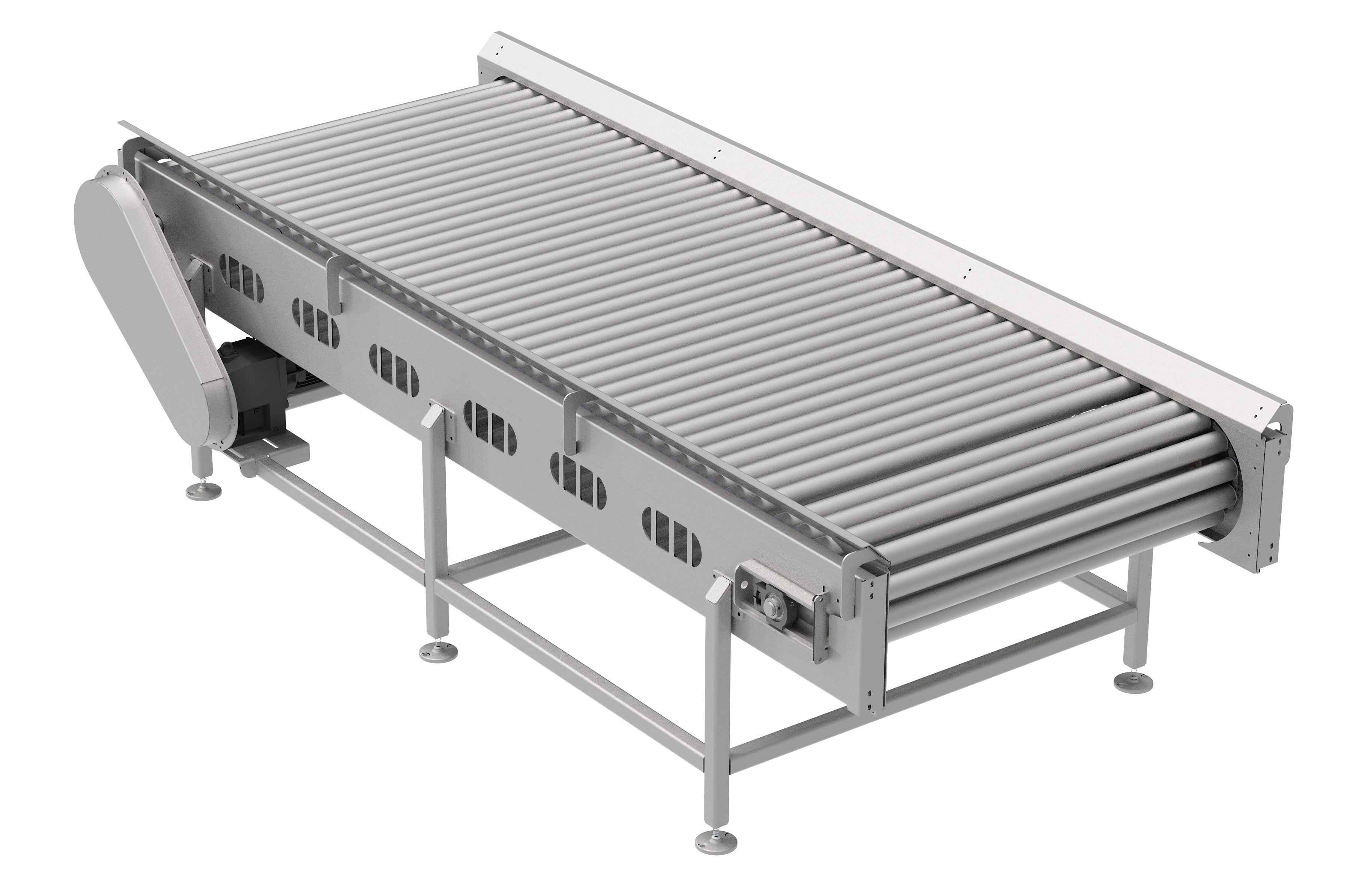

Live roller inspection conveyors are an economical solution and are crucial tools used in various industries and applications, including warehousing, manufacturing, quality control, and product inspection purposes. This versatile way to convey products of different shapes, sizes, and weights consists of rotating rollers that allow the products to be continuously rotated in front of the operator, facilitating a comprehensive inspection from all sides. When your situation calls for light to medium duty conveying of small or close roller centers, belt-driven live roller (BDLR) conveyors are ideally suited. Belt-driven is mechanically simple and effective for transporting materials over a long distance with a single motor. A belt under the roller drives the carrying rollers, which are pushed up under the roller with a lifting roller. This makes the belt run in the opposite direction of the material being moved. In addition, by lowering the drive belt from the roller, accumulation zones can be created. Transporting heavy materials requires a chain-driven live roller (CDLR) conveyor. This low-cost, high-load capacity requires welded construction to make it durable enough to handle the harshest conditions and heavy loads while maintaining positive driving power.

Looking for automated roller inspection systems for manufacturing? GWI offers cost-effective roller inspection solutions for industries designed to enhance productivity and ensure quality control. Our high-speed roller inspection technology for production lines and integrated roller inspection solutions for packaging provide reliable performance, reducing downtime and increasing operational efficiency.

Key features include:

- Advanced automation for precise and quick inspections.

- Customizable systems to fit various production needs.

- User-friendly interfaces for easy operation.

- Comprehensive maintenance services to ensure system longevity.

- Proven technology for accurate defect detection.

Competitive Advantages:

GWI’s roller inspection systems are engineered to optimize your production processes. With our innovative technology, you benefit from reduced operational costs and improved product quality. Our commitment to customer support and tailored solutions means you can trust GWI to meet your unique inspection needs efficiently and effectively.

Contact Us

Interested in learning more about how GWI’s Roller Inspection Systems can enhance your food processing operations? Contact us today to discuss your needs and discover how our high-efficiency, custom systems can help you achieve your production goals.

Support and Services

- Installation and Training: GWI provides comprehensive installation services and operator training to ensure seamless integration and optimal use of their equipment.

- Maintenance and Support: Ongoing maintenance support and troubleshooting services to keep equipment running efficiently.

- Customization Consultation: Expert consultation to design and customize processing lines tailored to specific requirements.