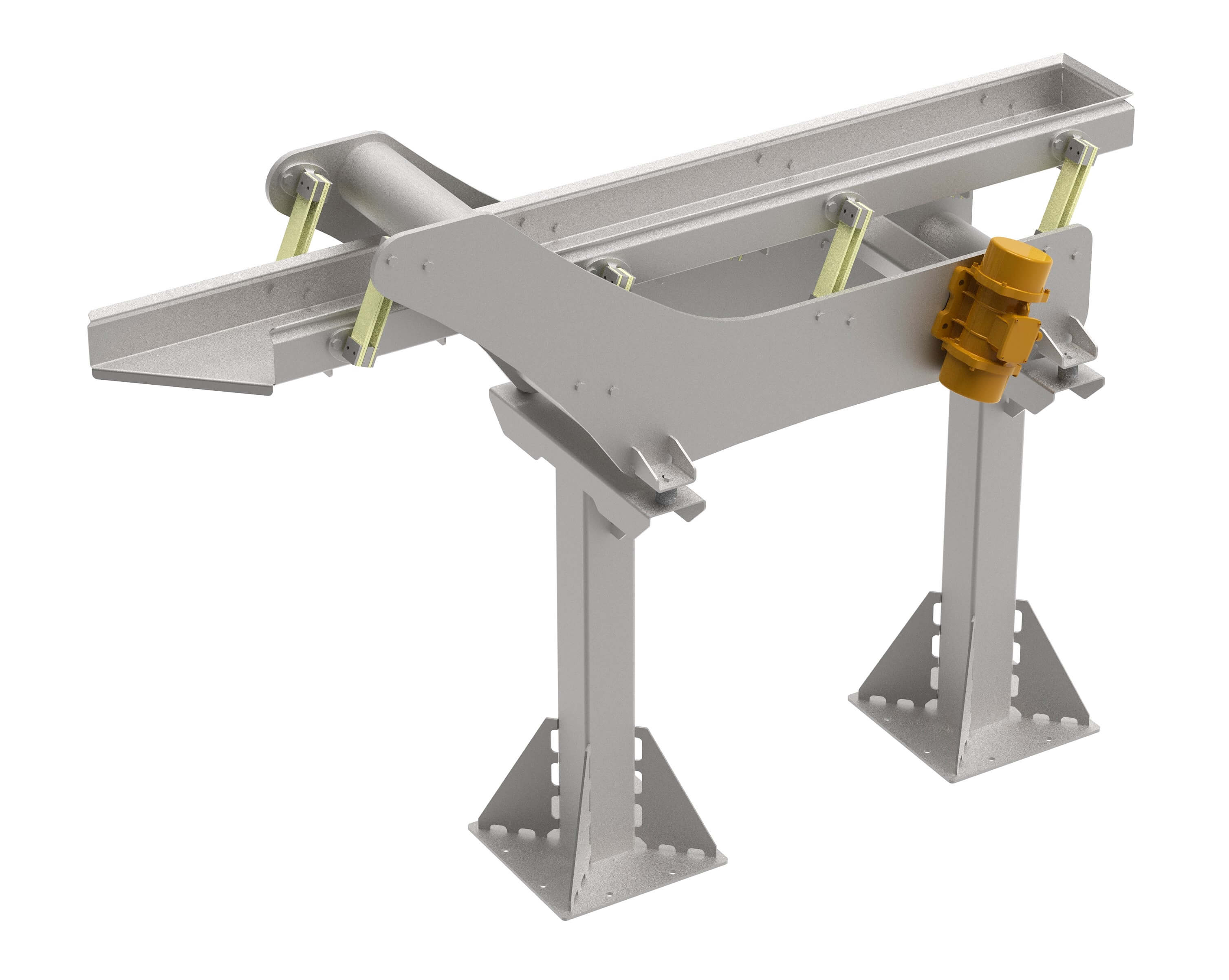

GWI’s Z-Type profile conveyors are engineered for efficient and precise transportation of products within food processing plants. Whether you’re handling bulk materials or specific food items, our Z-Type profile systems ensure smooth and consistent product flow. With custom configurations, automation options, and hygienic designs, GWI’s conveyors meet the demands of modern food processing industries.

GWI’s industrial Z-Type profile systems are ideal for handling large volumes of food products. Designed for the food industry, these systems ensure seamless movement of products, even in high-capacity processing lines.

Key Features:

- High-Capacity Performance: Capable of transporting bulk materials with precision and efficiency.

- Consistent Material Flow: Ensures smooth product movement, reducing bottlenecks.

- Durable Construction: Built to handle the demands of industrial food processing environments.

Competitive Advantages

GWI’s Z-Type profile conveyor systems provide a range of competitive advantages, including customization, precision, sanitation, durability, and automation. With a focus on efficiency and productivity, GWI’s systems help food processors improve product flow, reduce waste, and lower operational costs. Whether you need turnkey solutions or custom-built conveyors, GWI’s Z-Type profile systems offer the reliability and performance needed to excel in today’s competitive food processing industry.

GWI’s Z-Type profile systems offer several competitive advantages that make them a top choice for food processing and bulk material handling industries:

1. Customization and Flexibility

- Tailored Solutions: GWI provides fully customizable Z-Type profile conveyor systems that can be adapted to fit specific production line requirements. Whether you’re transporting delicate food products or handling bulk materials, GWI can configure the system to meet the exact needs of your facility.

- Versatile Applications: GWI’s Z-Type profile systems are suitable for a wide range of food processing applications. From conveying raw ingredients to moving packaged products, these systems are highly adaptable and can be used in various food industry settings.

2. Precision and Accuracy

- Accurate Product Movement: GWI’s Z-Type profile systems are designed for precision, ensuring accurate and efficient movement of products. This precise handling reduces product loss and ensures smooth product flow, helping maintain the overall quality of goods during the transportation process.

- Consistent Performance: GWI’s Z-Type profile conveyors offer consistent results, ensuring that food products move steadily through the production line. This minimizes the risk of bottlenecks and ensures that production remains on schedule.

3. Sanitation and Hygiene

- Food-Grade Materials: GWI’s Z-Type profile conveyors are constructed from food-safe materials such as stainless steel, ensuring they meet the highest hygiene standards. This makes them ideal for food processing environments where sanitation is essential to avoid contamination.

- Easy to Clean: Designed with smooth surfaces and minimal crevices, GWI’s Z-Type profile systems are easy to clean and maintain. This helps food processors comply with food safety regulations and maintain sanitary conditions throughout production.

4. Durability and Reliability

- Heavy-Duty Construction: GWI’s Z-Type profile systems are built to handle the rigors of industrial food processing. Using durable materials like stainless steel, these conveyors are designed for continuous, long-term operation in demanding production environments.

- Reliable Operation: Built for high-capacity use, GWI’s Z-Type profile systems deliver reliable performance with minimal downtime. This ensures that production lines stay operational, reducing interruptions and improving overall productivity.

5. Efficiency and Productivity

- High-Efficiency Conveying: GWI’s Z-Type profile systems are optimized for high-efficiency operation, ensuring that products are transported quickly and effectively. This reduces delays, increases throughput, and helps food processors maintain smooth and efficient production lines.

- Energy Efficiency: GWI’s Z-Type profile systems are designed to consume less energy while maintaining high performance, lowering operational costs, and supporting sustainable production practices.

6. Automation and Labor Savings

- Automated Control Systems: GWI’s Z-Type profile conveyors can be fully automated, reducing the need for manual intervention. Automation ensures consistent and efficient product movement while reducing labor costs.

- Labor Cost Reduction: Automation not only streamlines the material handling process but also reduces the need for manual handling, allowing workers to focus on other critical tasks. This leads to overall cost savings and improves resource allocation.

7. Turnkey Solutions

- Ready-to-Use Systems: GWI offers turnkey Z-Type profile conveyor systems that are fully assembled and tested, ready for immediate installation and operation. These solutions help food processors implement new systems with minimal downtime, allowing for faster production improvements.

- Expert Installation and Support: GWI provides expert installation services and ongoing technical support to ensure that the Z-Type profile systems operate at peak performance. This level of support helps customers maximize the value of their investment.

8. Cost-Effectiveness

- Reduced Product Waste: GWI’s precision Z-Type profile systems help minimize product loss by ensuring smooth and accurate product movement. This improves product yield and contributes to higher profitability for food processors.

- Lower Operational Costs: GWI’s systems are designed with energy efficiency and durability in mind, helping to reduce long-term operational and maintenance costs. This makes the Z-Type profile systems a cost-effective solution for food processors seeking to optimize production without increasing costs.

Why Choose GWI?

- Expertise and Experience: With extensive experience in designing and manufacturing food processing equipment, GWI provides innovative solutions tailored to your needs.

- Customer-Centric Solutions: Our team works closely with clients to deliver customized raisin processing solutions that enhance operational efficiency and productivity.

- Quality Assurance: Every system is rigorously tested to meet the highest standards of quality and performance before leaving our factory.

Contact Us

Interested in learning more about how GWI’s Z-Type profile conveyors can enhance your food processing operations? Contact us today to discuss your needs and find out how our high-efficiency, custom solutions can help you achieve your production goals.

Support and Services

- Installation and Training: GWI provides comprehensive installation services and operator training to ensure seamless integration and optimal use of their equipment.

- Maintenance and Support: Ongoing maintenance support and troubleshooting services to keep equipment running efficiently.

- Customization Consultation: Expert consultation to design and customize processing lines tailored to specific requirements.