Custom Food Processing Solutions.

Built to Perform

GWI has delivered industry-leading food processing systems designed for precision, efficiency, and long-term success. Partner with us for machinery that meets your exact production goals—with reliability you can count on.

Proven Industry Expertise

Decades of experience delivering high-performance systems for global food brands.

Tailored Engineering

Custom-built solutions designed for your unique production needs.

Sustainable Innovation

Advanced technology focused on efficiency and environmental impact.

WHERE PERFORMANCE MEETS PURPOSE

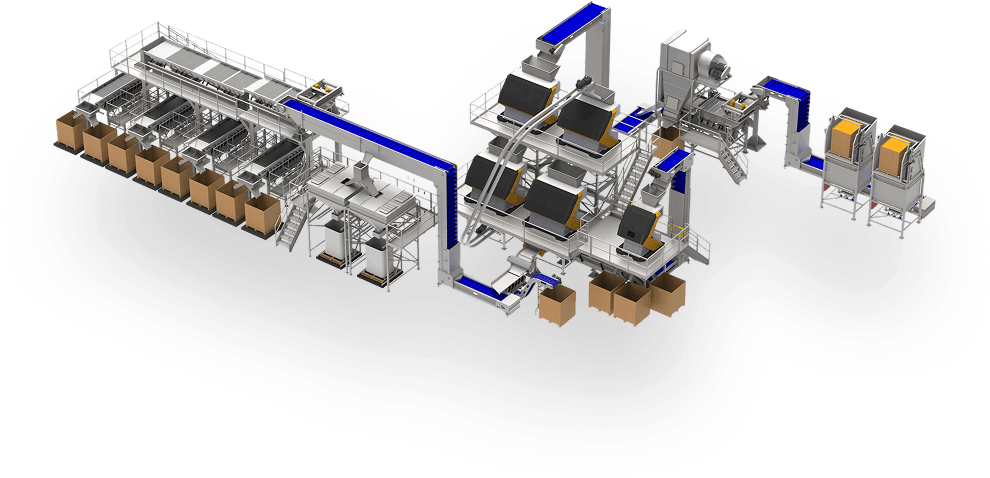

Made to specification Food Processing Machinery, material handling, steel fabrication, and service for 30 years.

For 30 years, GWI has been a trusted supplier of custom food processing machinery, material handling, steel fabrication, and exceptional service. Located in Fresno California, our cutting edge manufacturing facility is dedicated to delivering innovative equipment. At GWI, we specialize in designing, fabricating, testing, and fully manufacturing wide ranges of both standard and custom solutions.

30

Years

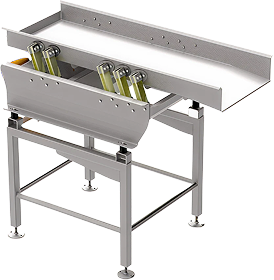

Processing Components

GWI’s background in manufacturing for the commercial food processing equipment and food industry equipment manufacturers has focused on products such as meats, wines, poultry, nuts, raisins, grapes, vegetables, fruits and more. Choose GWI as your main source for custom food processing machinery manufacturing and steel fabrication.

Nut Processing Components:

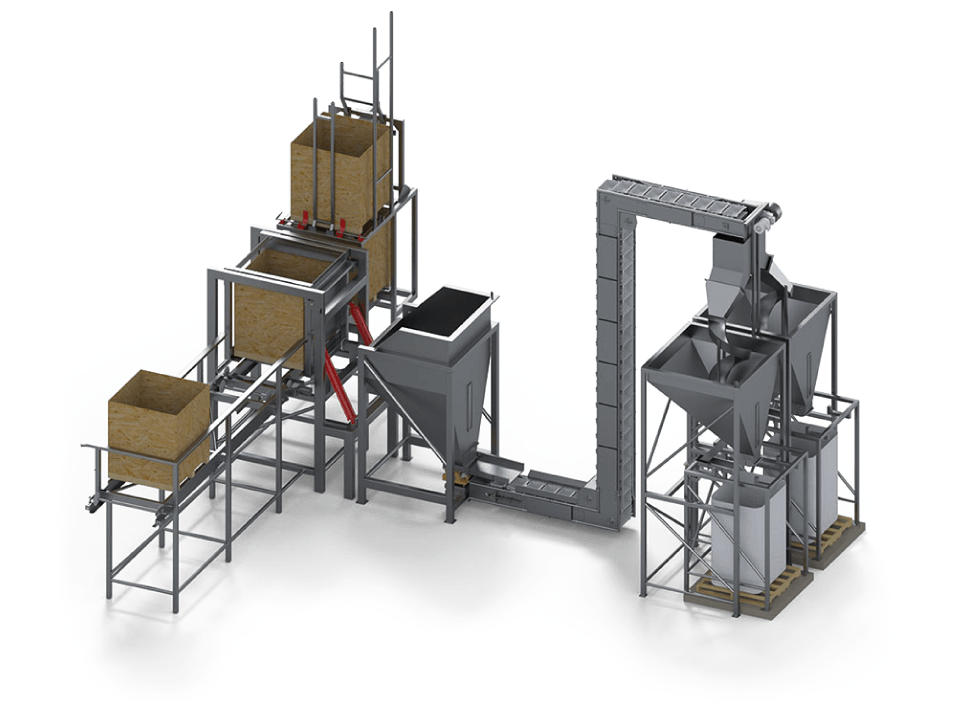

- Bin/bulk bag dumping and metering

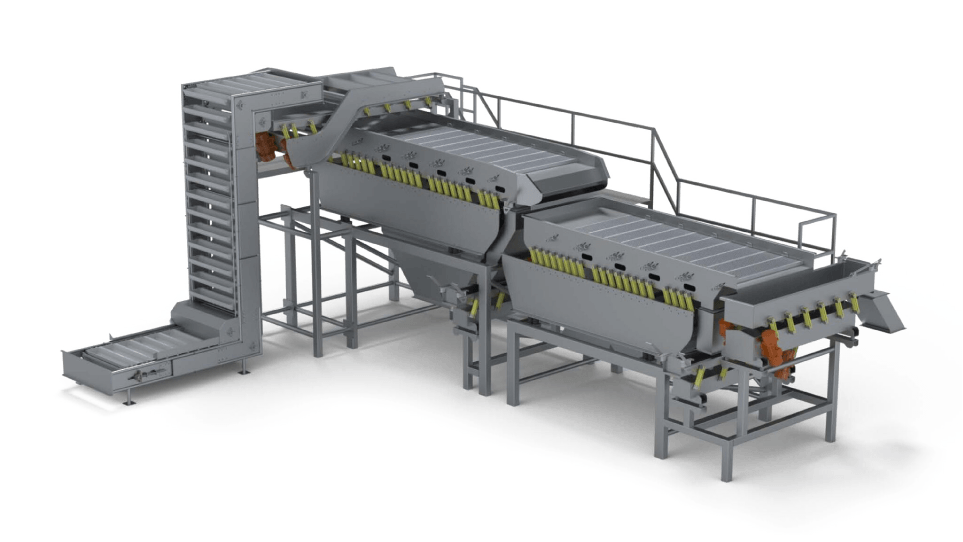

- G-Flex vibratory high-speed scalping systems

- UVS air aspiration separation systems

- G-Flex high efficiency size grading systems

- Optical sorting and X-ray integration equipment

- G-Flex vibratory metal detection equipment

- Product transfer elevators and conveyance

- Bulk filling and retail packing equipment

Mixing Processing Components :

- Frozen whole and or diced vegetables

- Frozen whole and or diced fruits

- Frozen whole peas (and similar type products)

- Frozen leafy products

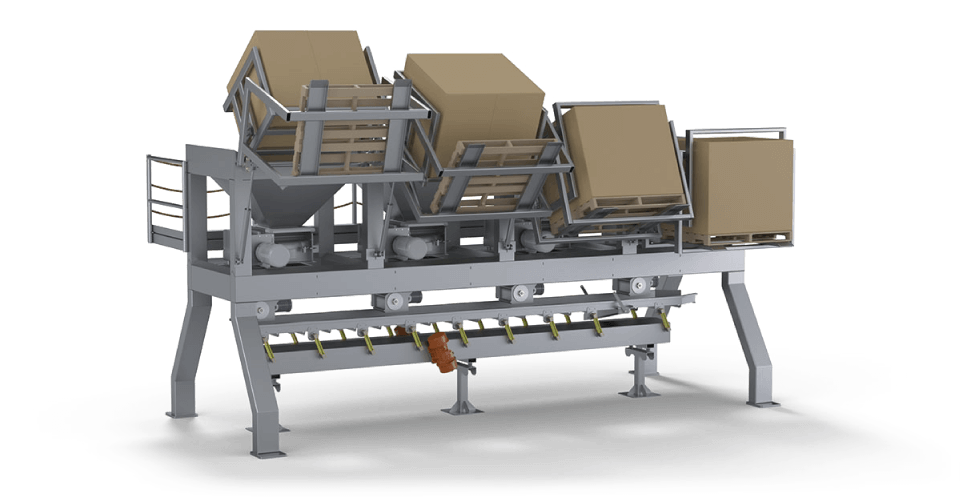

- Two stage product bin dumping with pallet separation

- Size adjustable frozen product cluster breakers

- Quick change out volumetric metering valves

- G-FLEX vibratory conveyor transfer systems (with fines removal separation if necessary)

Raisin Processing Components :

- Bin Dumping

- Product Metering

- Next Generation High Speed Scalping Systems

- UVS Stem and Debris Removal

- Product Elevators

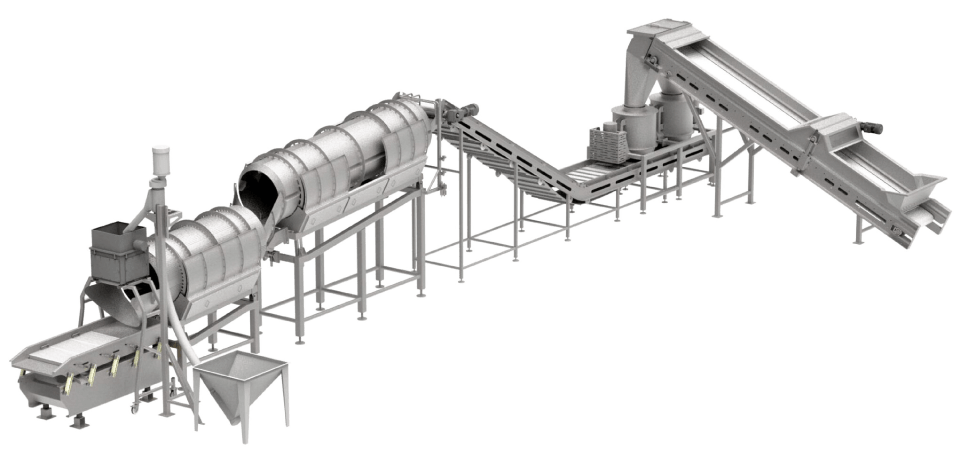

- Next Generation High Speed De-Watering Systems

- De-Stoning Riffle Systems

- Rotary Re-Cleaners

- Sugar and Flavor Coating

- High-Speed De-Clumping Process

- Color Sorting and X-RAY integration equipment

- Automated Bulk box Packaging

Bulk Processing Components :

- Jars

- Buckets

- Drums

- Trays

- Boxes

- Totes

- Wood/plastic bins

- Table top conveyors

- Chain top conveyors

- Belt conveyors

- Pop-up conveyors

- Vibratory transfer conveyors

- Bucket, Belt, and Scoop type elevators

- Single and Two stage dumpers

- Bulk collection hoppers

- Product metering systems

- Stacking systems

- Weighing Systems

Flavoring Processing Components :

- Bulk metering in-feed conveyors

- Leveling and layering of product

- Singulating any stuck together/clinging materials

- Inspection belt conveyor zones

- Liquid coating tumblers equipped with spray manifolds

- Flavor coating tumblers equipped with volumetric ingredient feeding

- Fines removal/excess flavoring collection prior to packaging

Olive Processing Components :

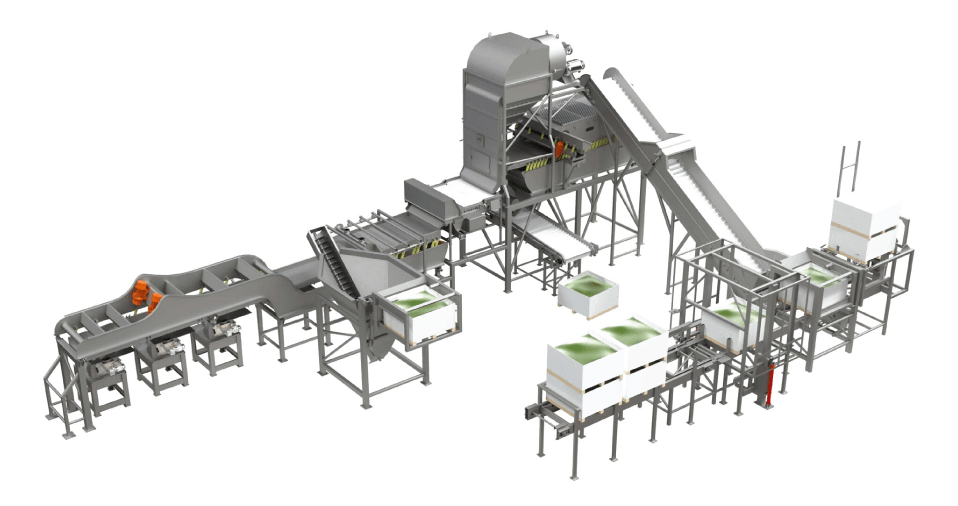

- Fully automated Bin de-stacking, Dumping, Re-stacking, and Metering systems

- Next Generation High Speed Scalping Systems equipped with our UVS Debris removal

- Washing and rinsing vibratory systems

- Water reclaim rotary reels

- Color Sorting, Metal detection and X-RAY Integration Equipment

- Product Transfer Elevators and or Conveyance

- Distribution vibratory G-FLEX® conveyors to feed crushing equipment

- Bulk packing scale systems

Services That Power Performance

GWI offers end-to-end support for your food processing operations—from precision equipment installation and engineering to preventive maintenance and emergency repairs. Our expert team ensures your systems run efficiently, stay compliant, and evolve with your production goals.

Backed by 30+ years of experience, we help you reduce downtime, boost efficiency, and stay ahead in the competitive food industry.